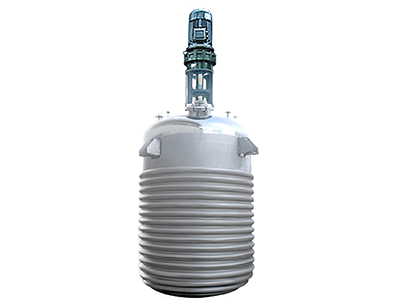

Jacketed Reactor

Jacketed reactor: used in the chemical industry, pharmaceutical industry and food industry, and other fields

Material

glass, stainless steel (316, 304), carbon steel, others

Capacity (L)

10-10000+

Mixing system

anchor, paddle, frame and others

Heating system

electric heating, oil heating and others

Jacketed reactors can be divided into steam heating reactors and heat transfer oil heating reactors according to different heating media, both of which are widely used in medicine, the chemical industry, plastics, rubber, building materials, food, and other industries. Corrosion, no environmental pollution, no need for automatic boiler heating, ease to use, and so on.

Request a quoteJacketed reactors are widely used in the petrochemical, pharmaceutical, and food industries. However, as the volume of the container increases and the heat exchange required increases, ordinary jacketed reactors can no longer meet their heat exchange requirements. At the same time, as the pressure inside the jacketed reactor increases, the wall thickness of the inner cylinder also needs to increase when designing considering the external pressure. This will cause the jacketed reactor to have a heavy structure and increase the cost. The honeycomb jacketed reactor is an improvement on the ordinary jacketed reactor. It is based on the overall jacket and adopts a uniformly distributed honeycomb structure between the inner cylinder and the jacket to enhance the bearing capacity of the inner cylinder and the jacket.

Learn about honeycomb jacketed reactor

The main function of the honeycomb jacketed reactor is to increase the flow speed of the fluid in the cavity while the medium supply conditions remain unchanged. At the same time, the fluid will collide with the honeycomb points multiple times to form local small vortices. This causes the medium flow in the cavity of the honeycomb jacketed reactor to form turbulent flow, destroying the original laminar flow layer and accelerating the heat exchange speed. Therefore, the heat exchange efficiency of the honeycomb jacketed reactor is higher than that of the traditional integral jacketed reactor. In addition, since the honeycomb bottom and the inner cylinder are all-welded, the honeycomb jacketed reactor and the cylinder are connected as a whole. Therefore, the load-bearing capacity of the inner cylinder and the jacket can be effectively improved, and the inner cylinder generally does not need to consider the instability caused by the internal pressure of the jacket for external pressure design.

Commonly used honeycomb jacketed reactors can generally be divided into two types: folding type and stretch type. In the folding type, the jacket is generally folded inward and then welded after being fitted to the entire body. The tensile type uses a small stamped cone or steel pipe as the tensile body. The welding points of the honeycomb jacketed reactor can be arranged in an equilateral triangle or square shape on the whole body, and in the form of concentric circles on the head.

The pressure vessel of the honeycomb jacketed reactor needs to be equipped with a pressure relief facility when multiple pressure vessels such as vessels, heat exchangers, towers, etc. share a safety valve. Valves, regulating valves, and other facilities that may isolate the pressure vessel from the safety valve cannot be installed on interconnected pipelines.

Controlling deformation of honeycomb jacketed reactor

Since the honeycomb jacket has numerous honeycomb holes, it is easy to deform when the shell and jacket are welded. In order to control deformation, in actual production, we mainly focus on the following aspects:

1. Strictly control the welding current: It is necessary to weld layer by layer during welding, and the current of each layer can be gradually increased appropriately;

2. Select the appropriate welding sequence: After each honeycomb hole is welded step by step along a circle, another hole in a low-temperature state can be selected for welding;

3. Take a rapid cooling method: the inner cylinder can be filled with water to speed up the cooling process of the weld.

As non-standard equipment, the honeycomb jacketed reactor has a volume ranging from 50L to 50000L. The specific design requirements and specifications must be customized according to the user and material attribute requirements. It is easy to operate and can be used for vacuuming, heating, cooling, etc. It has been widely used in resins, adhesives, paints, cosmetics, medicine, and other industries, and has a wide range of applications.