The working principle of the single-layer glass reactor is that the reaction solution is stirred at normal pressure or negative pressure inside the single-layer glass reactor, the outside is immersed in a bath and heated by a liquid medium, and the evaporation and reflux of the solution are controllable. The shells of this series of products are made of high-quality stainless steel, which is anti-corrosion and rust-proof; all glass parts are made of high borosilicate GG-17 glass, which is resistant to high temperature, and temperature difference, and is not easy to corrode; PTFE components are sealed with our proprietary technology, and the vacuum degree is good.

Scope of application: This product is suitable for chemical research, drug research, food science, biomedical and other institutions, and colleges.

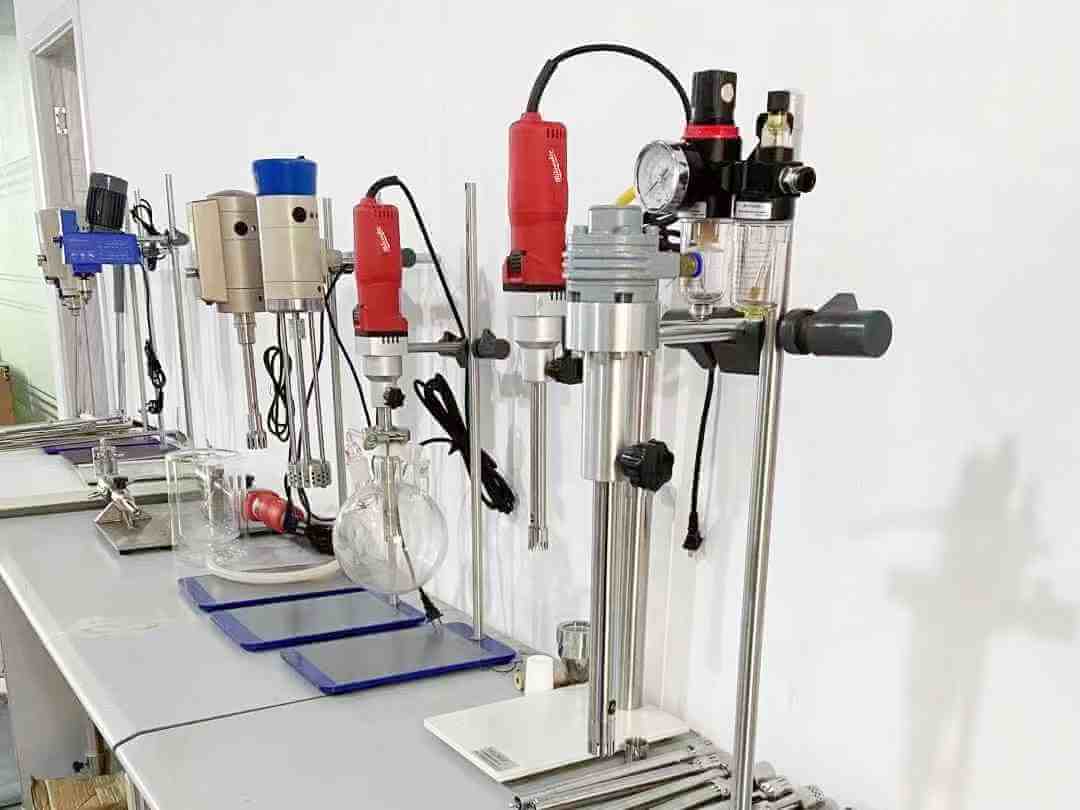

Technical characteristics of single-layer glass reactor

1. Because the material used in the glass reactor (G3.3 borosilicate glass) has excellent material and chemical properties. During the stirring process of variable frequency speed regulation, the operation will be relatively stable, and no spark will be generated even if the torque is large.

2. In addition, the components are sealed with tetrafluoroethylene, which can maintain a good vacuum degree (generally around -0.095mpa) in similar products in the market, and maintain high-precision sealing under working conditions. There is also a chip collection groove.

3. Alloy steel mechanical seal, PTFE connection port, maintain the high-precision seal under working conditions.

4. Pt100 sensor probe, high-temperature measurement accuracy, a small error, effectively improves work efficiency.

5. The PTFE discharge valve can move the interface, and the discharge is thorough and fast.

6. Relevant knowledge of glass reactor The cooling or heating solution of the interlayer can be completely drained after the reaction is completed, and no liquid will accumulate.

7. The overall stainless steel column mobile frame structure, five chemical reactor covers, with a full set of glass for reflux, liquid addition, temperature measurement, etc.

8. Strong torque, no noise. Adopted Japanese technology AC gear motor.

9. The double PTFE stirring paddle in the glass reactor knowledge lecture hall is suitable for stirring and mixing low to high-viscosity liquids.

10. The kettle body and interface can be customized according to customer requirements.

11. Regardless of refrigeration or heating, we can produce supporting products according to customer requirements.

12. The overall structure is scientific, novel, practical, and beautiful, leading the domestic industry.