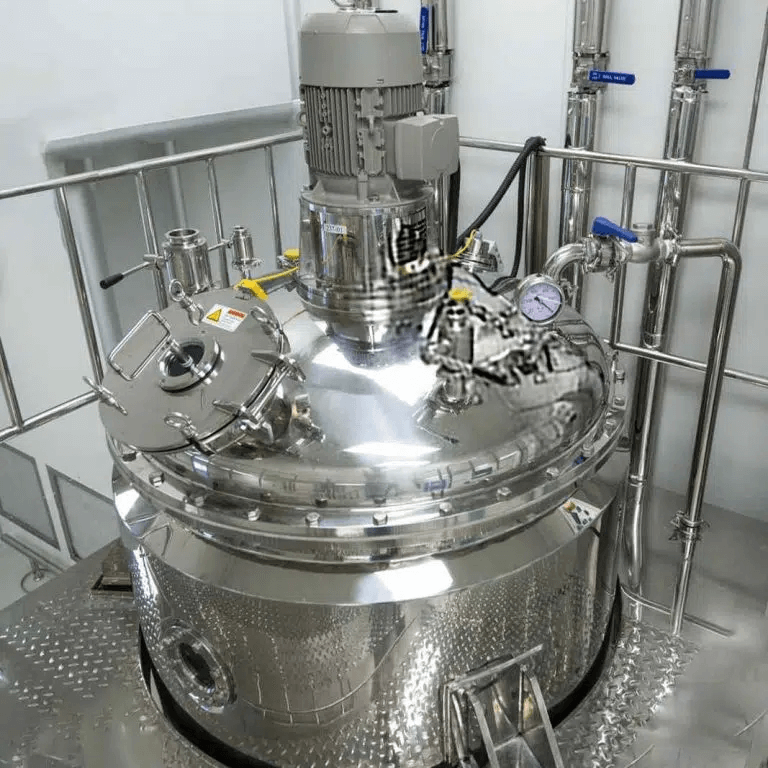

The high temperature and high pressure reactor are composed of: a special light source, a stainless steel kettle body, and a control system. It is used for pilot and scale-up production of high temperature and high pressure photochemical catalysis, synthesis, and degradation in the fields of new energy, environment, and new drug research and development.

Structural features of high temperature and high pressure reactor

1. The cauldron body and cauldron cover are made of stainless steel. The cauldron body is connected to the flange through threads. The cauldron cover is a straight flat cover. The two are tightly connected by main bolts and nuts evenly distributed around them.

2. The sealing port of the high temperature and high pressure reactor adopts A-type double-line sealing, and the other sealing points adopt the line contact sealing form of arc surface and flat surface, arc surface, and arc surface. Relying on the high precision and smoothness of the contact surface, the high temperature and high pressure reactor achieves a good sealing effect.

3. The lid of the high temperature and high pressure reactor kettle is equipped with a pressure gauge, bursting membrane safety device, temperature sensor, etc. It is convenient to understand the reaction situation in the kettle at any time, adjust the medium ratio in the kettle, and ensure operation.

4. There is a barrel-shaped silicon carbide furnace core outside the kettle. The electric furnace wire is passed through the furnace core, and its end is passed through the lower part of the furnace shell side. It is connected to the controller through wiring studs and rubber-covered cables.

5. The high temperature and high pressure reactor coupling is mainly composed of a pair of inner and outer magnetic rings with strong magnetic force, with a pressure-bearing spacer in the middle.

Advantages of high temperature and high pressure reactor

1. Easy to operate.

2. Double high-voltage windows on the side.

3. Quickly separate the high temperature and high pressure reactor from the heating furnace.

4. High temperature and high pressure reactor kettle placement rack.

5. With bottom tube sampling function.

6. Support catalyst filtration.

7. True color large capacitive touch screen.

8. Cast aluminum heater, high heating uniformity, and fast heat transfer.

9. Supports LED lighting for easy observation.

10. Supports heat preservation timing and start timing, dual timing mode.

11. Supports pressure digital display function, and multiple pressure units can be switched freely.

12. It has a safety interlocking function and over-temperature and over-pressure alarm.

13. Supports suspension stirring to avoid wear on the bottom of the mixer and catalyst wear.

-131-300x300.jpg)