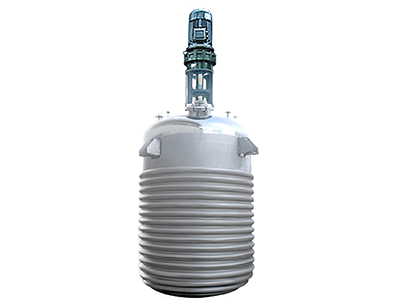

Jacketed Reactor

Jacketed reactor: used in the chemical industry, pharmaceutical industry and food industry, and other fields

Material

glass, stainless steel (316, 304), carbon steel, others

Capacity (L)

10-10000+

Mixing system

anchor, paddle, frame and others

Heating system

electric heating, oil heating and others

Jacketed reactors can be divided into steam heating reactors and heat transfer oil heating reactors according to different heating media, both of which are widely used in medicine, the chemical industry, plastics, rubber, building materials, food, and other industries. Corrosion, no environmental pollution, no need for automatic boiler heating, ease to use, and so on.

Request a quoteA jacketed reactor is a commonly used chemical reaction equipment. It is often used in chemical synthesis, drug research, plastic processing, resin, glue, and other fields. It has the characteristics of high efficiency, safety, and reliability. The characteristic of the jacketed reactor is that it has a jacket structure, which can quickly dissipate the heat generated during the reaction process by circulating water through the jacket to ensure the smooth progress of the reaction.

Working principle of jacketed reactor

The jacketed reactor is used to be fixed on various containers. There are a variety of stirring blades available to suit different process requirements. Jacketed reactors generally use double-end mechanical seals with self-lubricating systems, which do not require regular maintenance and have stable performance. Suitable for stirring, mixing, dissolving, dispersing, and color mixing of various materials. It is easy to operate and has strong adaptability. It is an ideal multi-functional equipment for mixing, dispersing, and so on.

The stirring blades of the jacketed reactor rotate in a fixed direction driven by the power unit. During the rotation process of the jacketed reactor, the material is driven to rotate axially and radially. The materials in the mixer have both axial and circular motion, so there are several mixing forms such as shear mixing and diffusion mixing. It can effectively disperse and stir materials.

The outside of the jacketed reactor is covered with a jacket, and the jacket is filled with heat transfer media such as thermal oil or hot water in turn. During use, this medium is circulated in the jacket space to conduct the heat generated inside the jacket reactor to the jacket medium and maintain the reaction temperature through circulation. The jacketed reactor is also equipped with a thermometer and pressure gauge, as well as sensing technology to monitor the pressure and temperature in the jacket and jacketed reactor.

Jacketed reactors have a wide range of applications. In the chemical industry, jacketed reactors are often used in various reaction systems such as normal pressure reactions, low-pressure reactions, high-pressure reactions, vacuum reactions, etc., and can be used for multiphase reactions such as liquid-liquid, liquid-gas, and liquid-solid. Specific reaction types include oxidation reaction, reduction reaction, esterification reaction, cyclization reaction, etc. In the pharmaceutical manufacturing industry, jacketed reactors are important tools for the production of various intermediates and raw materials. In the plastics processing industry, jacketed reactors are mainly used for polymer synthesis reactions. In the food field, jacketed reactors can be used to make seasonings, flavors, etc.

Precautions for jacketed reactor

First of all, the design and manufacturing of the jacketed reactor must be qualified to ensure its safety and stability in complex environments such as high pressure and high temperature. Secondly, during operation, you must strictly follow the instructions for use and comply with relevant safety regulations. In addition, after the reaction, the jacketed reactor and its jacket must be cleaned promptly to remove residues to avoid contamination of the heat transfer medium.

The application of jacketed reactors in the field of chemical reactions is irreplaceable. It is also widely used in scientific research, pharmaceutical manufacturing, plastic processing, and other fields. For different reaction systems and reaction processes, the jacketed reactor also needs to be designed and configured accordingly to ensure that the reaction effect reaches the expected goal.